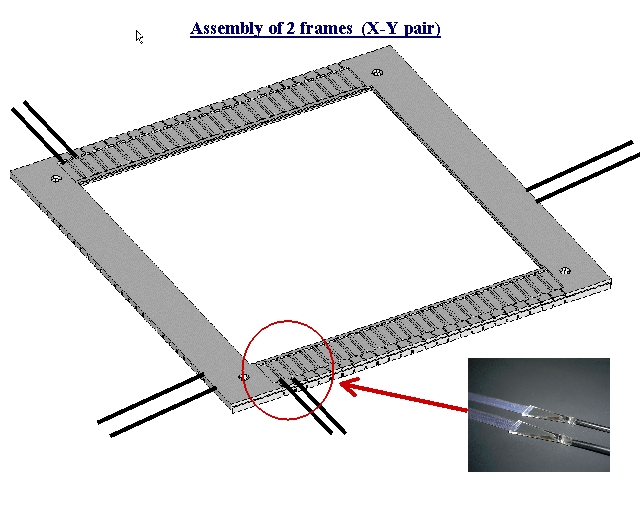

- A new mechanical design was implemented for the CREAM-2 calorimeter. Each Tungsten plate is glued into a Carbon fiber composite frame. The aim is to achieve a modular structure of completely independent light-tight elements. The building block is the assembly of two consecutive X-Y layers. Superlayers consist of 4 calorimeter layers each. The disassembly of the calorimeter can be done by breaking the calorimeter into superlayers or X-Y layer pairs.

(picture below)

- Scintillating fibers are assembled into 1cm wide ribbons (top and bottom right) and glued into the acrylic light-guides (left).

(pictures below)

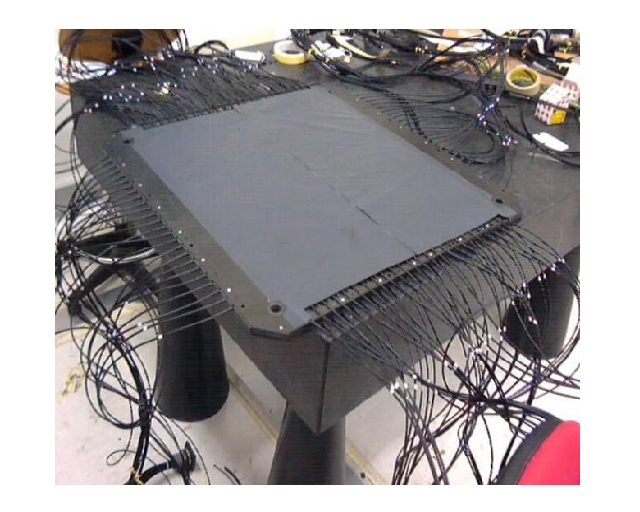

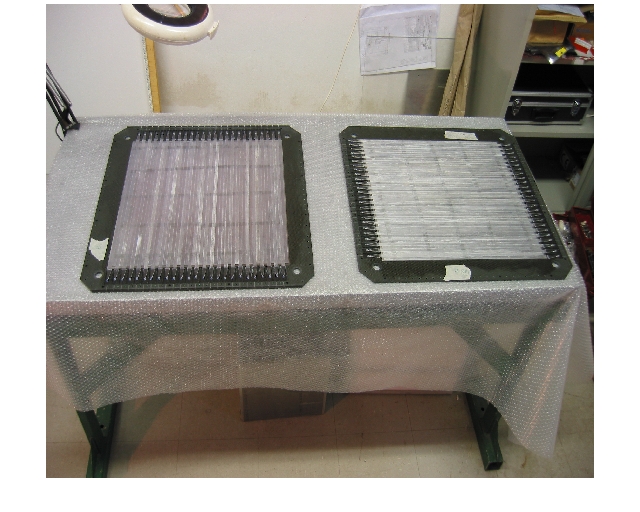

- Two calorimeter layers equipped with 50 fibers ribbons each (orthogonal views).

(picture below)

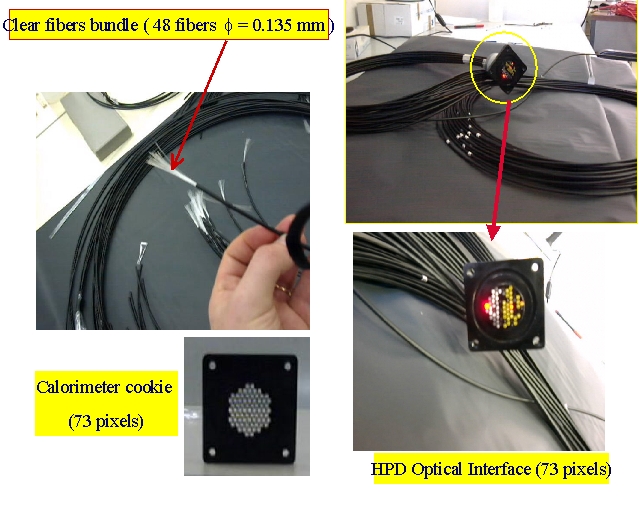

- Clear fiber bundles (48 fibers/bundle) are assembled into the connector (cookie) which provides the optical coupling of the clear fibers with the HPD pixels. One of the 3 LED's used for the HPD pixels alignment is visible (top and bottom right)

(picture below)

- The optical fiber bundles are glued to the light guides using a vertical fixture which allows up to 4 layers to be cured at a time.

(picture below)

- Final assembly of one X-Y pair of layers.

(picture below)

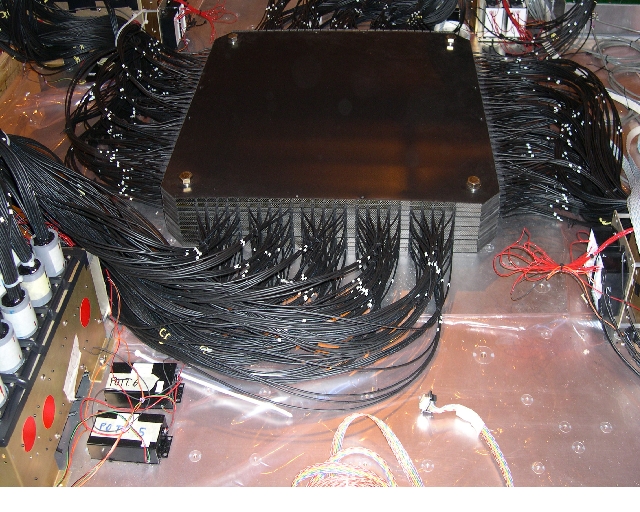

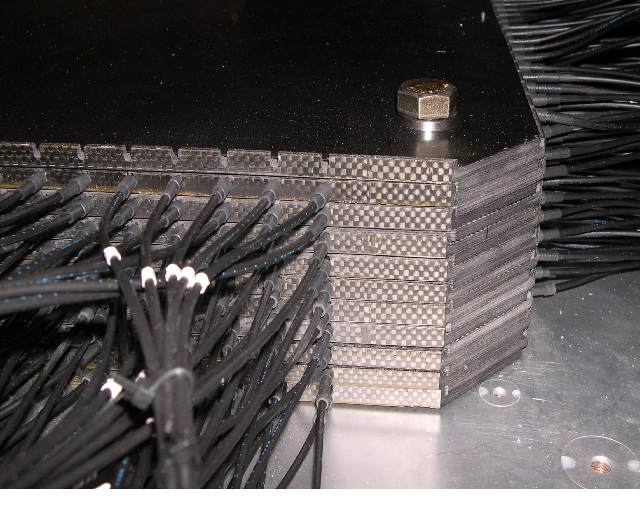

- The calorimeter stack during the final assembly.

(next 4 pictures)

- The CREAM-2 calorimeter (20 radiation lengths) fully assembled with 40 HPDs and the read-out electronics on top the the CREAM honeycomb pallet (July 2003).

(picture below)

- A particular showing how the clear fiber bundles are inserted into the light-tight modular structure of the calorimeter.

(picture below)

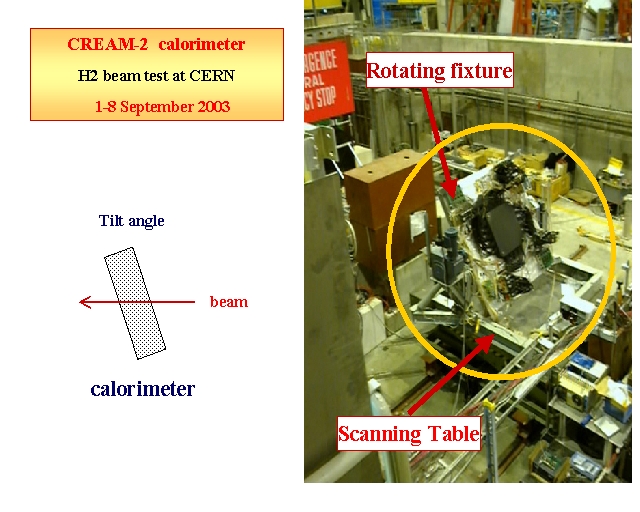

- CREAM-2 calorimeter at CERN H2 beam during the September 2003 test.

(picture below)

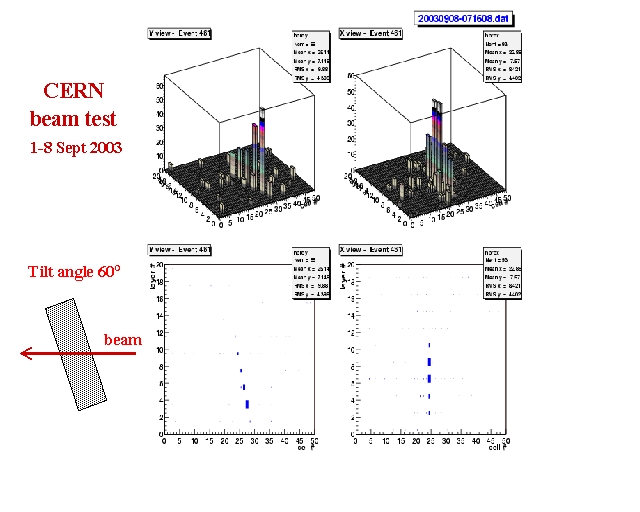

- Online event display of the imaging calorimeter showing narrow e.m. showers generated by the electron beam.

(picture below)

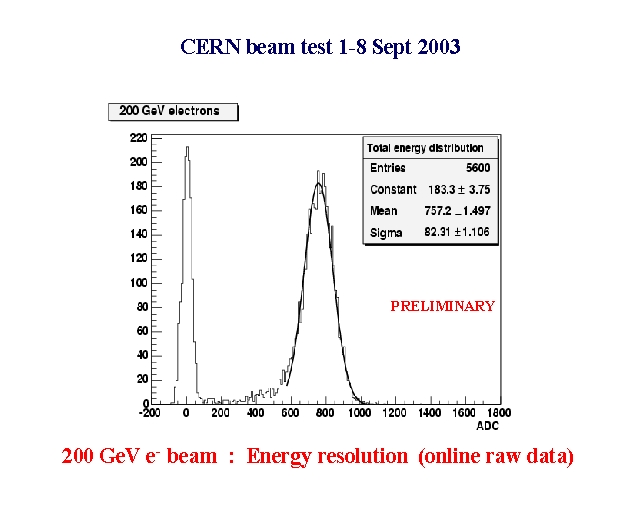

- Raw data (uncalibrated) display of the total energy distribution with 200 GeV electrons.

(picture below)